Making Tools For A Bearing Swap

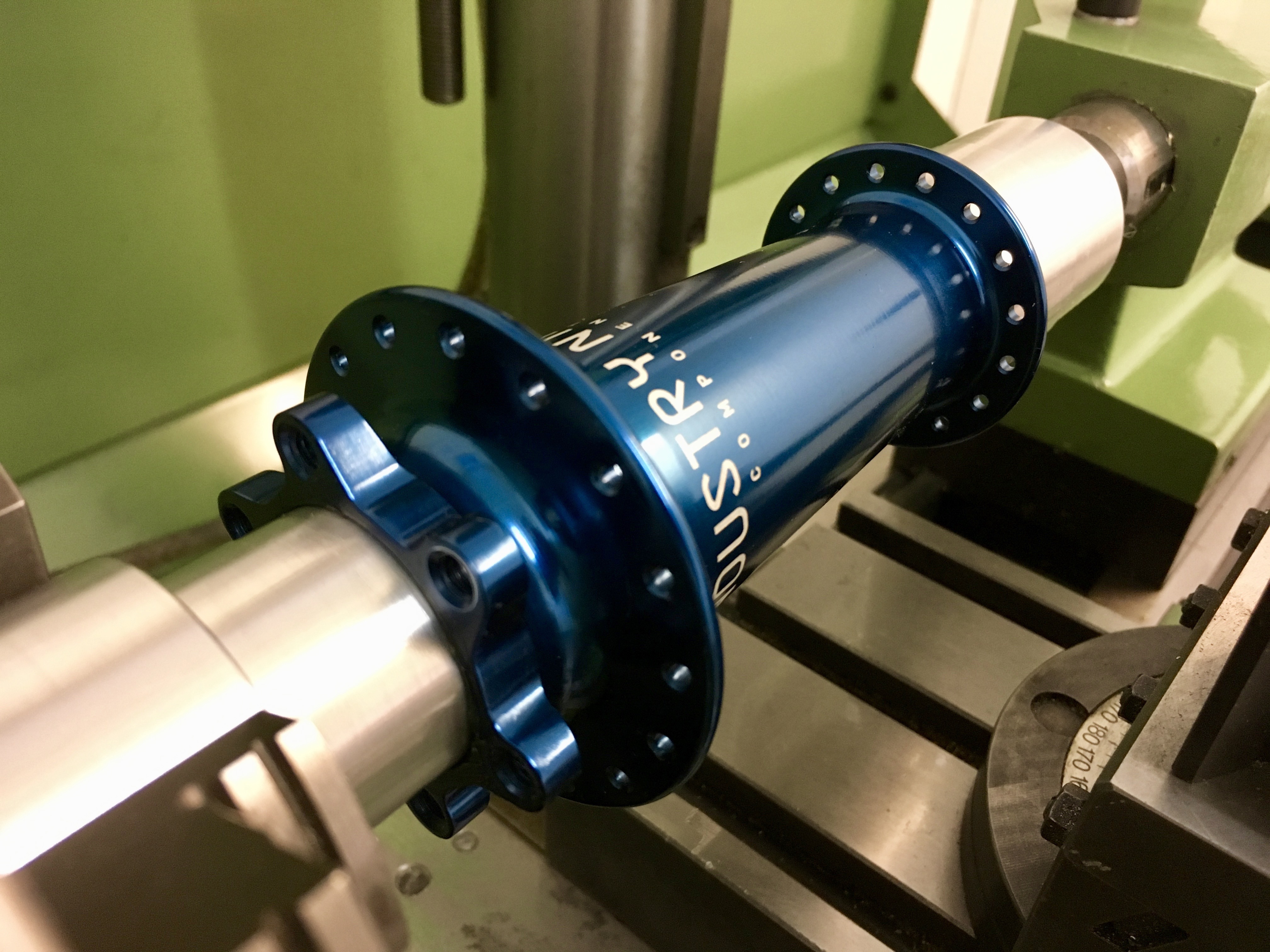

When the rear HED Big Deal carbon rim on my BigBoy got damaged while riding due to the pilot not being careful, I unlaced both wheels. Those Big Deal rims are not designed for trail riding and I knew it. Since trail and off-trail riding is the future of BigBoy, the broken rim was an opportunity to build a burlier set of wheels. It was also just the right time to treat the Industry Nine Classic Torch hubs with new bearings.

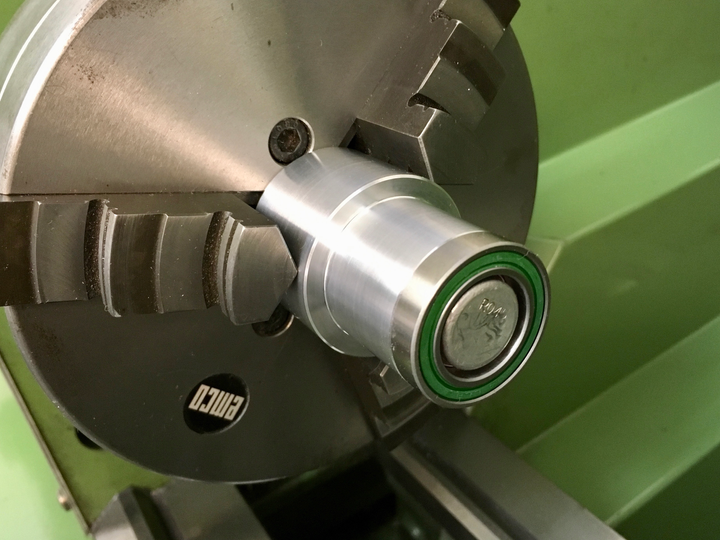

I ordered Enduro bearings and a bearing puller to remove the old bearings. What I needed, though, to get the job done were press-in tools to install the new bearings. To properly do such a job, one needs adapters that have nearly the same OD as the bearings. They have to push the outer bearing race into the hub body in order not to damage the bearing. We have a small conventional lathe at work, so I used that to make all the necessary parts. Once the parts were made, the tailstock of the lathe acted as a press to install the bearings.

It took me a full morning, but it was time well spent. A couple of days later, I gave the two hubs to my trusted wheel-builder at 47º Nord. He laced them to Bontrager Jackalope rims using DT Competition spokes. The result - an awesome tubeless-ready fat-bike wheelset.

Comments